If you work in the construction and manufacturing industries, you know that sometimes noise is simply part of the job. But excessive noise, especially over time, is more than just a nuisance. Repeated exposure to loud sounds can cause accidents on the job and can even result in permanent hearing loss long term.

Sound control insulation reduces the transmission of unwanted sound while also protecting workers. This type of insulation controls the quality and nature of sound caused by machinery, vibration levels and the structure of a building (e.g., vibration of machinery against floors, walls and ceilings).

Let’s take a closer look at how sound control works and why it’s so important in commercial and industrial settings, especially when it comes to protecting workers’ health.

1. Create a safe working environment.

In industrial and commercial settings, workers’ safety must come first. The dangers of working in noisy conditions over time can be hugely detrimental to a person’s health. In fact, the Occupational Safety and Health Administration (OSHA) has outlined the risks of ongoing exposure to loud noise. Excessive noise kills inner ear nerve endings (the more exposure, the more dead nerves), and increases the risk of permanent hearing loss.

As a result, OSHA outlines noise regulation compliance in commercial and industrial settings. When noise exposure is at or above 85 decibels averaged over eight working hours, or an eight-hour time-weighted average (TWA), employers must create a hearing conservation program.

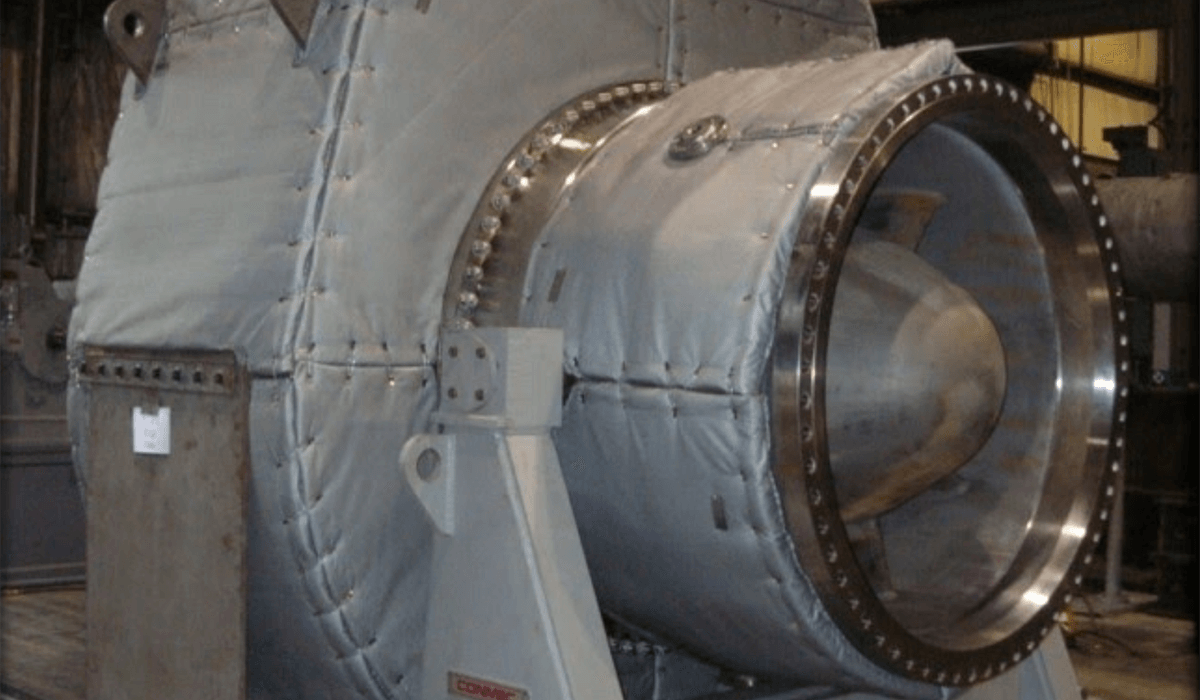

By installing sound control insulation, employers can prevent hazards in the workplace — such as workers not being able to communicate with one another when noise levels are high — while protecting workers’ hearing. Large baffles, blanket enclosures and acoustical enclosures are placed on the ceilings, walls or outer structure of large machinery to reduce or eliminate the reverberation of machinery against other building infrastructure. These materials come in an interior grade, exterior grade or even a silicon face for high-temperature applications.

2. Identify your greatest sound control needs.

Before you can decide how best to insulate, you must first determine the noise level, type of noise and relative loudness. Then, decide whether you will focus your efforts on soundproofing or sound control. Let’s break down the differences between the two.

Sound control, also known as “sound absorption,” absorbs sound from within a room by applying materials to walls or ceilings. Examples of sound control include acoustic wall panels, stretched fabric systems, acoustic ceiling systems and acoustic baffles. Sound control insulation is extremely effective at mitigating echo and reducing the noise level.

Soundproofing, also known as “sound blocking,” blocks out a sound completely. This method includes materials such as mineral wool, fiberglass, elastomeric (rubber), cotton and cellulose materials. Soundproofing is used to block out sound completely, especially in large places.

3. Choose an insulation method to meet the demand.

Once you’ve identified the source and quality of the sound you’re trying to insulate, you have three options: contain the sound, reduce noise reverberation or separate machinery from one another and exterior walls.

Method 1: Contain Sound

Containing sound can be done using blanket enclosures, sound enclosures and barrier blankets. Materials such as duct and pipe wrap, composite foam and portable blanket screens are used as reinforcement. This is a highly effective and noninvasive method of blocking and absorbing sound.

In extreme cases, industrial enclosures provide an added level of sound control. When the noise is contained within a single room, a soundproof door or seal kit is usually effective on its own.

Method 2: Reduce Noise Reverberation Level

Another option is to reduce the noise reverberation level. This works especially well in open spaces and in cases where machinery cannot be completely enclosed. The most common forms of sound control insulation in this case include acoustic panels, foam, sound blanket absorbers and sound baffles.

When baffles are hung from the ceiling, they absorb sound and prevent it from reverberating into other parts of the room or building.

Method 3: Eliminate Noise by Separating the Machinery

The third option is to reduce noise pollution that results from machinery vibrating against the structure of a building. In this case, the best forms of sound control insulation include a vibration damping sheet, a metal damping compound or a vibration isolation pad to eliminate friction between machinery and the sides of a building.

Noise that begins as a moderate annoyance can lead to serious safety concerns over time. Distribution International is dedicated to delivering high-quality insulation products that keep workers safe on the job.

To access current pricing for more than 29,000 products and quickly view all your quotes and orders in one place, register for CustomerConnect. Our customer-focused online platform gives you the power to do business where and when you want.