Commercial and industrial spaces of all sizes are susceptible to fires. Combustible dust, flammable liquids and gases and hot work equipment (heating, burning, soldering) are cause for concern. Workplaces that do not take the proper fireproofing precautions put their workers at risk.

Insulation fireproofing mitigates the high-temperature exposure in steel and concrete structures that can lead to fires. As an added benefit, this type of insulation regulates temperature, which in turn saves on total energy costs. Fireproofing any commercial or industrial space is a clear first step when establishing safety and maintenance protocols.

To understand various methods of insulation, let’s look at widely used insulation fireproofing materials and the difference between fire-stopping and fireproofing.

Fiberglass

Fiberglass is the most common form of commercial insulation. It’s made up of fine strands of glass woven together into tight patterns. It’s available in various options, i.e. “blown in,” “batt” (sheets), and “Board” (slabs). However, fiberglass batts that are covered with kraft paper or a foil facing are combustible. Standard batts have R-values ranging from R-2.9 and R-3.8 per inch and can withstand temperatures of up to 220 degrees Fahrenheit. Fiberglass is a great insulation option because of its availability and affordability.

Mineral Wool

Mineral wool is noncombustible and can be used in tandem with other forms of fire-resistant insulation. Mineral wool can also refer to glass wool, rock wool, or slag wool. Glass wool in particular can withstand temperatures of up to 1,220 degrees. Mineral wool has an R-value ranging from R-2.8 to R-3.5.

Foam

Foam is composed of cellulose, which comes from recycled newspaper and low-density plastics. The material’s composition plus a flame retardant create a resistance of up to 300 degrees. However, foam is still combustible at higher temperatures. Rigid foam insulation (polystyrene) is sometimes used in place of cellulose foam due to the latter’s mild side effects.

Fire-Stopping vs. Fireproofing

Fire-stopping and fireproofing both play an integral role in protecting your facility in the event of a fire. Understanding how each functions can protect your employees, building and equipment.

Fire-stopping prevents the spread of fire from one space or room to another. It can function as a sealant at any axis where fires are most likely to spread, such as ceiling joists, wall-to-wall connects and points at which the wall joins the floor. Whereas fire-stopping prevents the spread of fire and harmful gases, fireproofing protects a building’s structure from deterioration or collapse. Insulation fireproofing targets steel and concrete, which become some of the most vulnerable materials in a fire; steel can weaken and crack, and concrete can expand and burst. Fireproofing keeps workers safe and protects equipment in the long run.

Methods of Insulation

Each method of insulation fireproofing provides a different set of benefits based on application and the composition of materials. Here are three methods to consider based on your specific project.

-

Spray-Applied Fireproofing

Spray-applied fireproofing, also known as spray-applied fire-resistive materials (SFRM), contains cement or gypsum, mineral wool, quartz, perlite, or vermiculite. Spray-applied fireproofing is usually composed as a wet or dry spray. It’s delivered as a dry powder, then mixed with water at the worksite.

Spray-applied fireproofing is typically applied to steel structural members (beams, columns, steel floor deck, etc.). It can also provide thermal resistance and acoustical properties. However, its main use is in insulating steel, metal decking and other assemblies from the high temperatures found during a fire.

-

Intumescent Fireproofing

Intumescent fireproofing acts as an insulator that expands when exposed to high temperatures — up to 100 times its original thickness. As the product expands, it loses density and can act as an insulator between hot temperatures and a building’s structure.

Intumescent fireproofing is a popular method of insulation fireproofing because of its aesthetics when steel is exposed in public spaces. The product is applied just like paint, which makes installation and maintenance easy to facilitate.

-

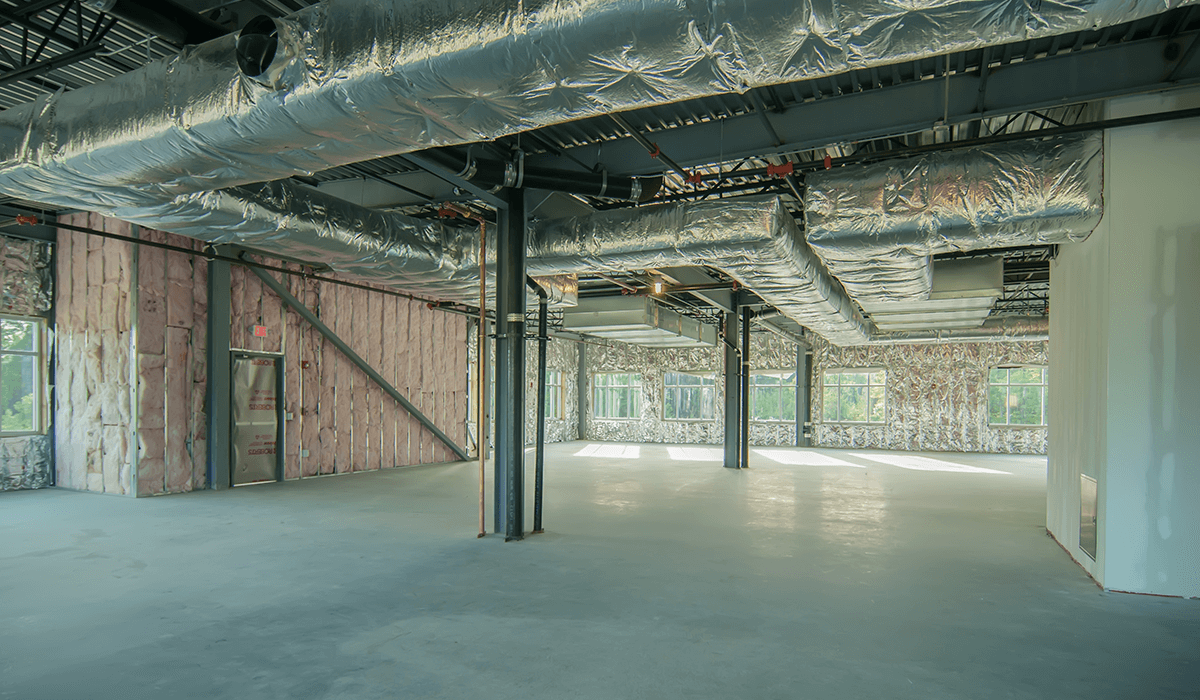

Reflective Insulation

As you may guess, reflective insulation gets its name from its ability to reflect heat and reduce fire risk. This type of insulation is made by bonding reflective materials (usually aluminum) with plastic film, cardboard and kraft paper. Most often, reflective insulation is used between studs, wall joists and roof rafters. It can also function as a surfacing agent on insulation boards to reduce heat transfer.

Reflective insulation is most effective when used in conjunction with other insulation materials. Installers must take weather conditions and placement when installing reflective insulation to ensure its effectiveness.

Choosing a method of insulation that suits your commercial or industrial application can sometimes feel overwhelming. We’re here to help. Distribution International offers a diverse inventory of insulation products and accessories to help you to complete any project, no matter the size.

To see up-to-date pricing and manage your quotes and orders online, register for CustomerConnect today.