When it comes to choosing how you will insulate a bend in a pipe on big jobs, you have choices: mitered elbow or engineered elbow? Although either might work for your needs, you can likely identify one clear winner based on particular features or the scale of your application.

Need a solution that’s easy to install? How about better thermal performance? Want to reduce shipping cost and breakage? We’re diving into the differences between mitered elbows and engineered elbows, from benefits and drawbacks to ideal use cases.

What Is a Mitered Elbow?

A mitered elbow — or mitered bend — is an elbow made of narrow mitered sections of fabricated insulation materials (i.e. Foamglas, Polyisocyanurate, Perlite, etc.) applied to a bend in a pipe. It is a common solution in applications where you can’t use straight, rigid insulation because it doesn’t bend. But because they must be cut so narrow, mitered elbows require more pieces, resulting in high labor requirements for installation and many through-joints that can reduce thermal performance.

Mitered elbows come with a few additional challenges:

- Highly skilled manpower required to produce

- Fragile pieces break easily, especially during transportation or job site handling

- Must be shipped assembled or mostly assembled, driving up total cost

- Extended installation time

- In extremely large bore pipe applications, mitered pieces may need to be intentionally broken to access the area for installation, e.g. to fit through scaffolding or other space constraints

So, is there another alternative to mitered insulation elbows?

What Are DI Fit Engineered Elbows?

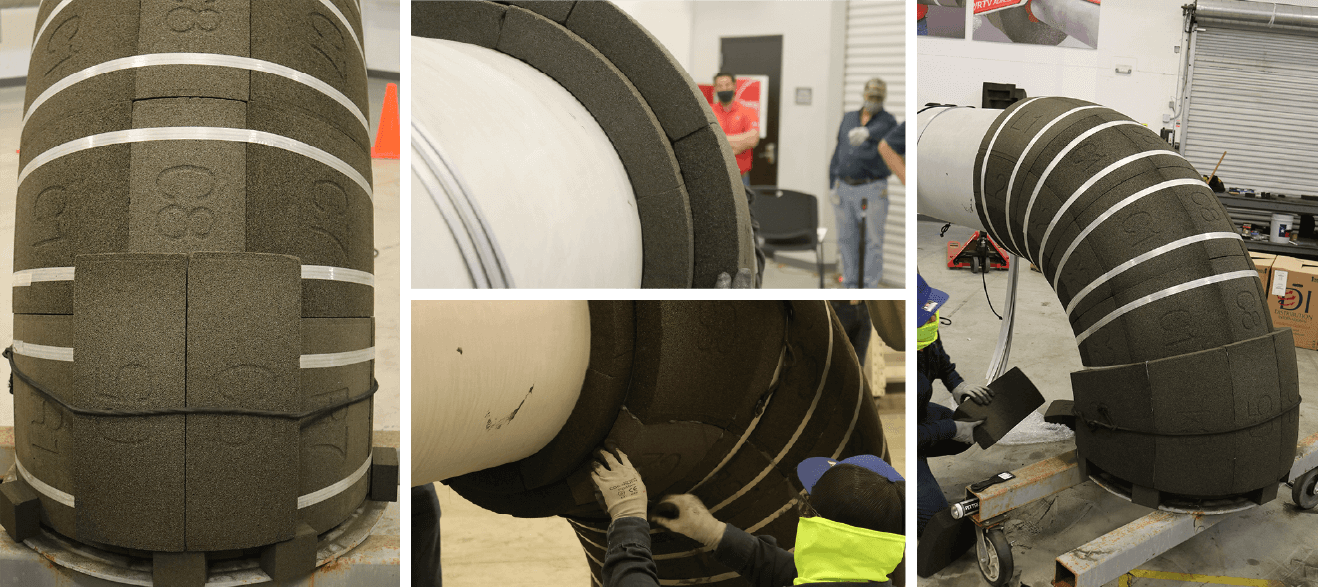

DI Fit Engineered Elbows solve the problems that often plague standard mitered elbows. They are made-to-order, fabricated elbow pipe fittings consisting of wide-cut, curved tiles that ship more efficiently and are easier to install than traditional mitered elbows. With a simpler design, engineered elbows require less sundry materials and installation time. They’re designed with zero through-joints on multi-layered applications and instead have joints that are staggered, reducing corrosion, increasing thermal performance and improving quality.

With mitered elbows, it’s not uncommon to run into productivity and quality challenges. But with DI Fit Engineered Elbows, you get a solution that is safer and more ergonomic to transport and install.

Freight Savings and Reduced Shipping Damage

DI Fit Engineered Elbows perform better before they even get to your door. Deal with significantly less breakage during shipping and transport with pieces that can be stacked with paper between each piece and packaged in bubble wrap to avoid vibration damage. Individual boxes of a reasonable weight reduce the amount of wasted shipping space, lowering shipping costs.

Simpler Installation = Labor Savings

DI Fit Engineered Elbows keep you on time and on budget by making installation a snap, improving efficiency and keeping the overall project production moving. DI Fit Engineered Elbows take 20-40 percent less time to install compared to mitered elbows and require a whopping 50 percent less labor.

Want proof? View our Installation Time Study video.

DI Fit Engineered Elbows address your pipe insulation needs without complicating your project. Get faster installation and better performance from Distribution International.

Common Use Cases for DI Fit Engineered Elbows

We recognize that mitered elbows and DI Fit Engineered Elbows work in unique applications. For our part, we think big. That is to say, DI Fit Engineered Elbows are most effective in large-scale applications.

Facilities and their associated contractors that need at least 18-inch-diameter pipe insulation benefit most from this solution. Some examples include:

- Liquefied natural gas (LNG) plants

- Oil and gas refining

- Chemical and Petrochemical processing

- Biofuels production

- Pulp, Paper and Power production

- Food processing

Applications aren’t limited to just these industries. Are engineered elbows right for your use case? Get in touch to discuss your needs.

Choose a Solution That Lasts

Need a made-to-order solution that provides maximum effectiveness and operational efficiency for your large-scale application? Save time and labor with DI Fit Engineered Elbows. Get in touch with our experts to discuss your application, and don’t forget to register for CustomerConnect for service perks along the way.